Product introduction

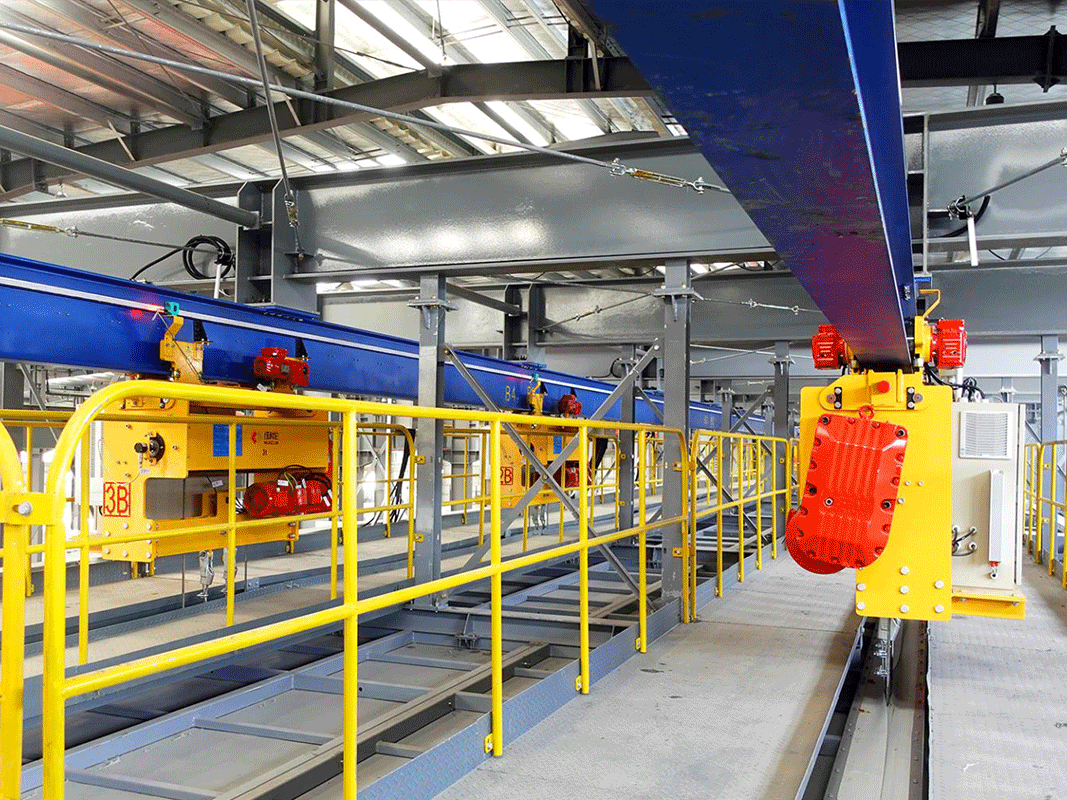

Crane for galvanizing is the Nucleon-developed special lifting product in response to the complex process and harsh working environment of the galvanizing industry, as well as the requirements of high efficiency and intelligent automation of material

Independent design

Modular design

Intelligent

Compact design

environment protection

Safety design

Product Details:

Crane for galvanizing adopts lightweight, modular and parametric design. Hoisting mechanism uses electric hoist for galvanizing with superior performance, advanced technology, safety, reliability, energy-saving and environmental protection. Traveling mechanism of the trolley is drove by three-in-one drive device and the control mechanism adopts the advanced variable frequency and speed regulation control system.

Crane for galvanizing includes electric hoist for galvanizing, electric single beam crane for galvanizing, gantry crane for galvanizing and multi-fulcrum suspension crane for galvanizing.

Product Features:

(1)High efficiency

Electric hoist for galvanizing and single beam crane for galvanizing are centered on the hot plating process, with fast lifting speed and running speed, and the working level of the whole machine can reach M7.

(2)Automation

The application of automatic control technology makes the crane positioning accurate and well-placed, ensuring the stability of the galvanizing process and the proper logistics transfer.

(3)Customization

Transferable track, cross track, lifting crane, hoist, single-beam, multi-fulcrum suspension, gantry type...

Product Features:

(1)High efficiency

Electric hoist for galvanizing and single beam crane for galvanizing are centered on the hot plating process, with fast lifting speed and running speed, and the working level of the whole machine can reach M7.

(2)Automation

The application of automatic control technology makes the crane positioning accurate and well-placed, ensuring the stability of the galvanizing process and the proper logistics transfer.

(3)Customization

Transferable track, cross track, lifting crane, hoist, single-beam, multi-fulcrum suspension, gantry type... We can perfectly match the logistics transportation route of the galvanizing workshop.

Performance Parameters:

Electric hoist for galvanizing

Lifting capacity: 3t~10t

Lifting height: 6m-18m

Lifting speed: 1.35m/min~13.5m/min

Running speed: 3m/min~30m/min, 4m/min~40 m/min

Work level: M5~M7

Single beam crane for galvanizing

Lifting capacity: 3t~10t

Span: 3m~30m

Lifting height: 6m-18m

Lifting speed: 1.35m/min~13.5m/min

Running speed: 3m/min~30m/min, 4m/min~40 m/min

Work level: A5~A7

Ensure that the crane moves slowly and accurately as it approaches its destination. This function can be applied to hoisting mechanism, trolley and crab. Inching movement can be set as required.

Dead slow function can ensure the stability of the control system and slow, accurate movement when the crane is moving and loading. This function can be applied to hoisting mechanism, trolley and crab.

"Zero speed hover" function automatically starts to prevent slip hook when the control system detects the slip hook trend (the motor does not rotate when the brake is opened).

Our cranes are all equipped with functions of upper pre-limit, upper limit, top impact-proof?limit impact-proof of the crane, which meets various needs of customers for products.

Crane can automatically limit the sway of the loader in the process of handling, realizing faster handling and more accurate positioning, and to be stable during the handling process.

Cranes are equipped with hazardous area restriction function, which can reduce the dangerous situation during loader movement, and prevent the damage of the loader, crane and surrounding area facilities.

Our cranes can add sub-low speed and sub-high speed function regulation except for low speed and high speed, which is practical and efficient.

The crane can monitor and control position difference of multiple hooks to make the hooks run synchronously at the same speed, ensuring the efficiency and quality of the crane.

When multiple cranes lift a loader at the same time, the position difference of multiple cranes can be monitored and controlled to make the crane operating mechanism run synchronously at the same speed.

A wireless module can be added to the crane to connect to the Crane Industrial Internet Platform, realizing the full life cycle management of the crane.

TikTok QR Code

TikTok QR Code

WeChat QR Code

WeChat QR Code

Homepage QR Code

Homepage QR Code

Tel:+860373-8622016

Fax:0373-8622001

Email: nucleon@nucleon.com.cn

Address:crane indusry park, Changyuan City, Henan Province, China